Established in 2014, Manti Tarka Permian is a joint venture between Manti Resources, Inc. and Tarka Resources, Inc. This enduring partnership between a tech-savvy, execution-driven operator and a capital-rich, strategic investor has proven to be successful by together delivering disciplined asset acquisition, efficient development, and aligned long-term growth.

This unique partnership is also the only known long-term, privately held partnership between a U.S. family-owned independent oil company and a major Middle Eastern family-owned conglomerate investing directly in U.S. upstream assets in the world.

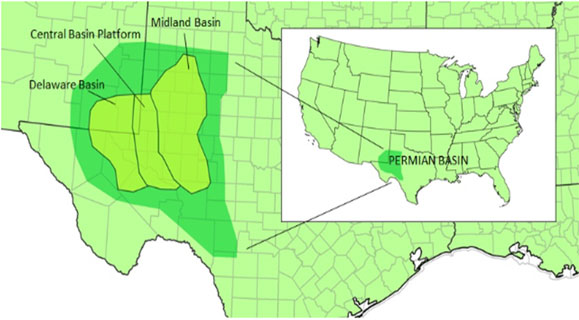

Manti Tarka Permian operates acreage located in the sweet spot of the Southern Delaware Basin, where multiple Permian age targets exist. The area of operations was delineated by industry success, Wolfcamp and Bone Spring maximum thickness maps, and the geographic location of the oil window.

Combined, the Bone Spring and Wolfcamp formations represent 2,000’ of oil saturated sediments with 5 proven and de-risked benches and at least 3 more potential horizontal target zones. These stacked reservoirs drive value and efficiencies and make the Delaware Basin one of the most prolific resource plays in the U.S.

Manti Tarka Permian has been operating a continuous drill line in the Delaware Basin beginning in 2015, delivering industry-leading well results while identifying future opportunities. Within just a few wells, Manti Tarka Permian achieved well performance equivalent to the top operators in the basin with an emphasis on performance optimization and continuous refinement at each stage of development. See News for more information on development program and industry records broken.

Manti Tarka Permian utilizes a multifaceted technical team that integrates geoscience, reservoir engineering, and drilling/completion expertise to optimize field evaluation and execution efficiency. The team embeds continuous feedback loops — comparing actual production versus design, learning from each completion, and continually refining future operations.

Manti Tarka Permian is currently accelerating its development and expansion plan of its operated assets in the core of the Southern Delaware Basin, specifically in Pecos, Reeves, and Ward counties. The team is focused on strategic partnerships, continuous acquisitions of core positions, and growing margins further through extended lateral drilling.